Harnessing Efficiency: Chiorino’s Energy-Saving Belts Transforming Industrial Operations

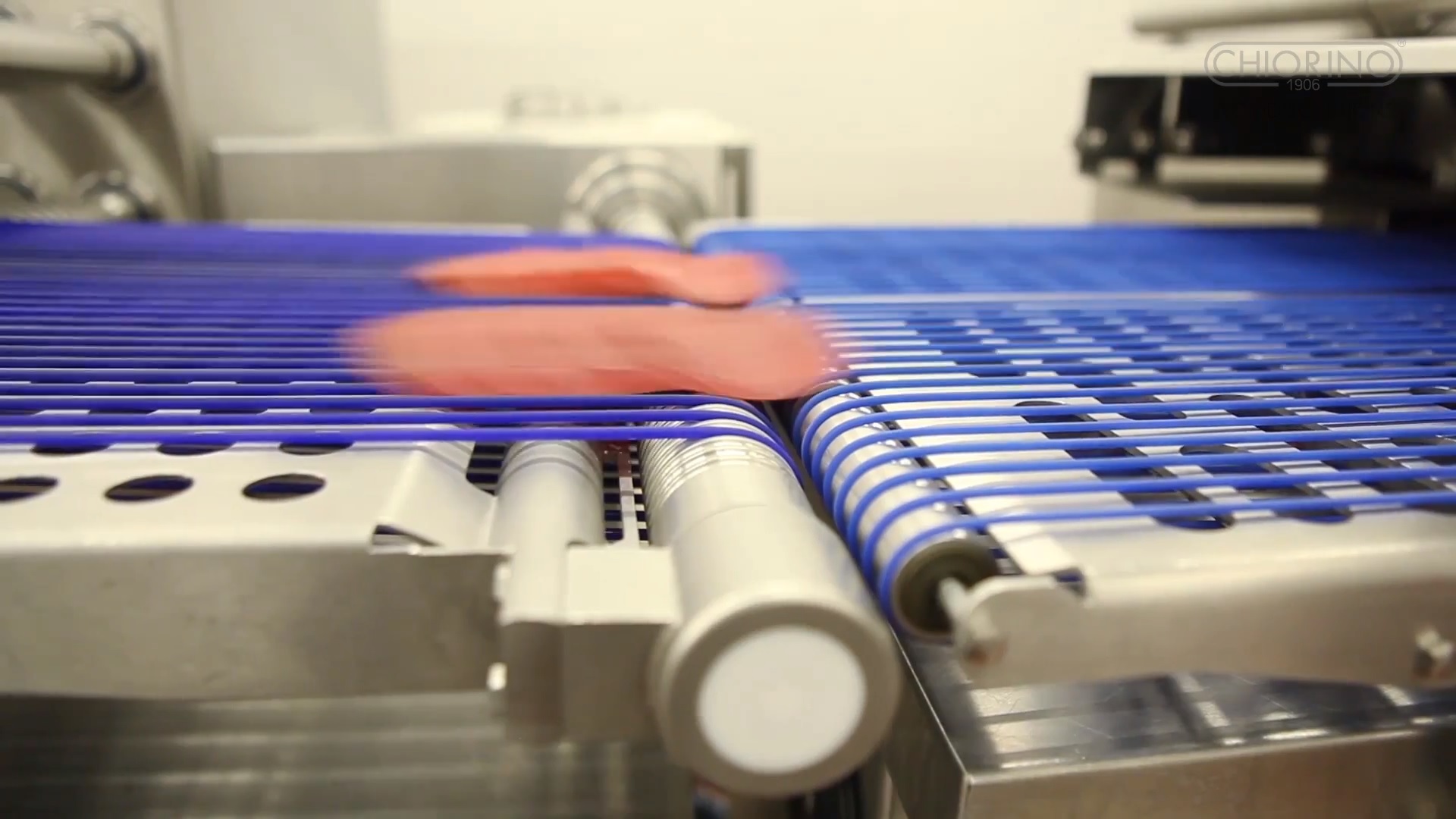

In the realm of industrial processes, efficiency is paramount, and every component plays a crucial role in optimising performance. Chiorino, a leading global supplier of conveyor and transmission belts, has developed a range of energy-saving belts. These innovative belts are revolutionising the way industries operate, offering a sustainable solution that not only enhances productivity but also contributes to environmental conservation.

Understanding the Need for Energy-Saving Belts:

Traditional conveyor belts, while essential for material handling in various industries, often come with inherent inefficiencies. Excessive friction, heat generation, and wear and tear contribute to increased energy consumption, resulting in higher operational costs and environmental impact. Recognising this challenge, Chiorino has dedicated substantial resources to engineer a range of energy-saving belts designed to address these issues.

Key Features of Chiorino’s Energy-Saving Belts:

Low Friction Materials: Chiorino’s energy-saving belts are crafted using advanced materials with low friction coefficients. This design minimises the resistance between the belt and the conveyor components, reducing the amount of energy required to drive the system.

Innovative Coating Technologies: The application of cutting-edge coating technologies on Chiorino’s belts enhances their durability and reduces wear and tear. This not only extends the lifespan of the belts but also ensures consistent performance over time, further contributing to energy efficiency.

Optimised Belt Design: Chiorino places a strong emphasis on the design of its energy-saving belts, ensuring they are tailored to specific industrial applications. By optimising the belt structure, Chiorino minimises energy loss during operation, resulting in improved overall efficiency.

Temperature Control: Excessive heat generated during conveyor operations can lead to energy loss and accelerated wear. Chiorino’s energy-saving belts are engineered to manage heat effectively, preventing unnecessary energy dissipation and promoting a more sustainable industrial environment.

Benefits of Chiorino’s Energy-Saving Belts:

Reduced Operational Costs: The decreased energy consumption facilitated by Chiorino’s belts directly translates into cost savings for industries. Companies adopting these energy-saving solutions experience a notable reduction in their operational expenditures, contributing to improved financial sustainability.

Environmental Impact: By curbing energy consumption, Chiorino’s belts align with the global movement toward sustainability. Industries utilising these belts can reduce their carbon footprint, demonstrating a commitment to environmental responsibility.

Enhanced Performance and Productivity: The longevity and consistent performance of Chiorino’s energy-saving belts lead to improved overall productivity. Reduced downtime for maintenance and replacements means industries can focus on their core operations, fostering a more efficient workflow.

Conclusion:

Chiorino’s energy-saving belts represent a significant leap forward in the quest for sustainable industrial practices. By addressing the challenges associated with traditional conveyor belts, Chiorino has not only enhanced operational efficiency but also positioned itself as a key player in the movement toward environmentally conscious manufacturing. As industries increasingly prioritize energy savings and environmental responsibility, Chiorino’s innovative solutions are poised to shape the future of material handling and conveyor systems.