How is Automated Technology Impacting the Manufacturing Industry?

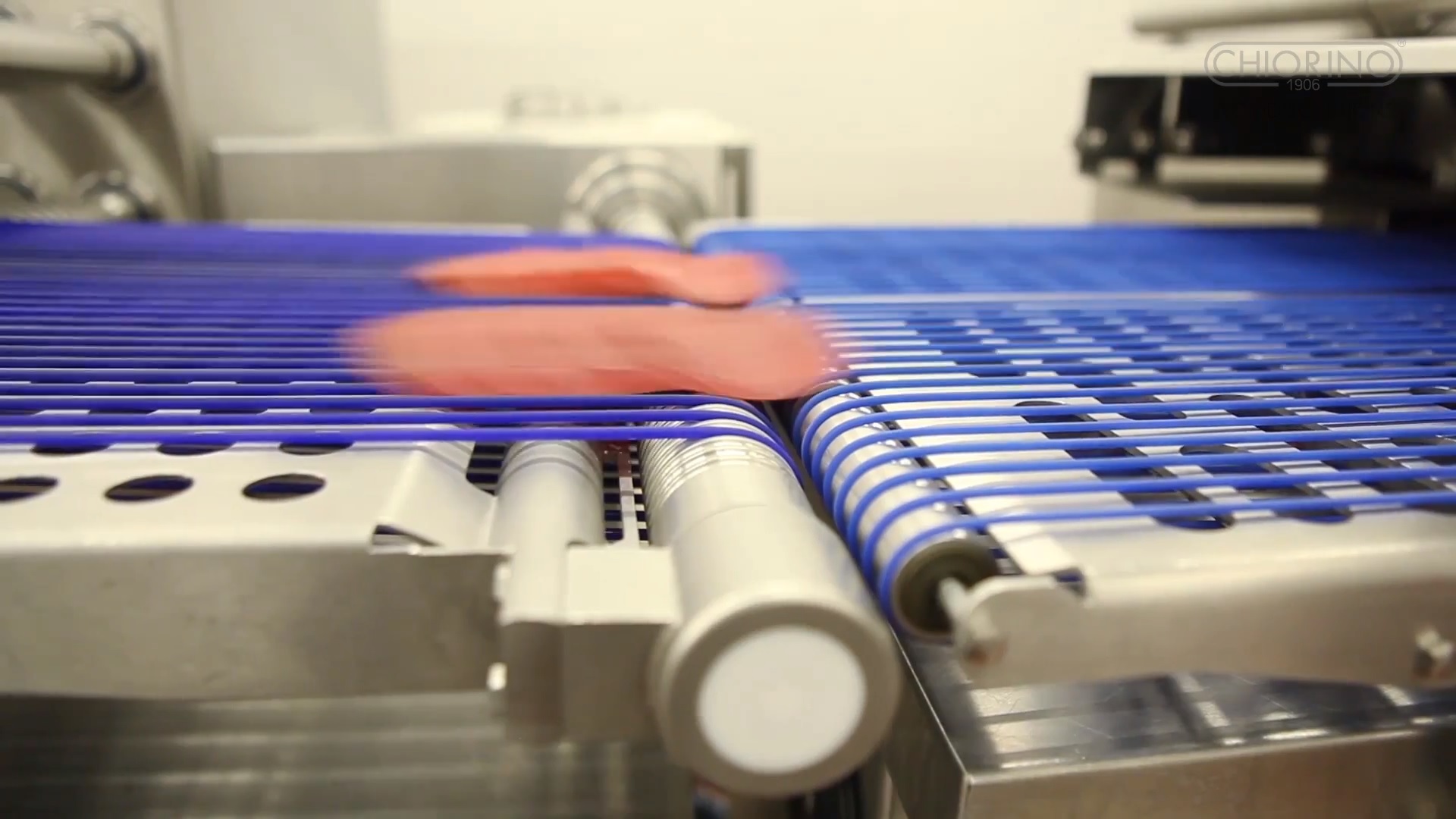

Our position as a leading supplier of innovative conveyor belt technology has allowed us to be in a fortunate place when it comes to the future of manufacturing within the food, textile and lubricant industries.

According to FoodManufacture.co.uk, a dedicated platform to providing news regarding food and drink manufacturing, technology that increases safety, efficiency, and cost of labour is in much higher demand for suppliers.

A shortage in labour has required logistics and manufacturing companies to focus their budgets on equipment that has an element of automation built into it. At Chiorino, the belts within our DET range would fall into this category due to their ability to detect the smallest fragments of metal debris that can infiltrate products.

Overlooking a potential fault or contaminant of a product can result in some very costly product recalls or lawsuits. Combining this with the need to quickly and efficiently produce high quality food, drink, or textile products intensifies the need for an efficient detection system.

According to the same source, the Food Standards Agency issued 145 food related alerts in 2017; almost triple the amount of same related cases in 2013. This is a worry for manufacturers across the country who will be seeking to minimise bad publicity and protect their profits.

Taking this into consideration, it is worth Managers of manufacturing companies to look into the options available to them in terms of creating an efficient, hygienic, and cost-effective method of production.

Browse our wide range of innovative belts on our website, or alternatively, you can contact us on 01977 691 880 for enquiries.