What Industries Use Chiorino Products?

We often speak about how well suited our products are for the food industry. And rightly so, our newly developed HP Compact Drive was made specifically with the food industry in mind. However, supplying belts for the food industry is far from all we do.

We supply belts and resistant materials that have a huge range of uses, and so can be applied to a number of industries. These include:

Packaging – we offer a range of conveyor and timing belts that can be tailored to suit safe and hygienic packaging of any kind. We offer belts for check-weighers, vertical form-fill sealers, accumulation and inclined belts, packaging machines with thermo-retractable films, labelling machines and capping machines.

Paper and Printing – the paper and printing industry is one of the most technically demanding on conveyor belts. The slicing element adds a whole new form of stress onto the belt which needs to be accounted for, which isn’t to mention the printing or gluing elements which are often involved.

Textile – our belts can be adapted and manufactured to be used in yarn processing, textile printing and for non-woven applications with ease. Nearly all our belts are manufactured in the UK by craftsmen who are fully trained on each of their stations.

Materials Handling – this is one area in which factories and plants are constantly trying to optimise and save money, and Chiorino can help you do just that. Our conveyor and transmission belts easily satisfy the most stringent demands for high speed sorting systems ensuring quality, high performance and low energy consumption.

Airports – the need for robust, reliable belts in airports is obvious. A malfunction at any point would cause huge delays to an untold number of people. This is why hundreds or airports already use Chiorino belts, which are renowned of their reliability.

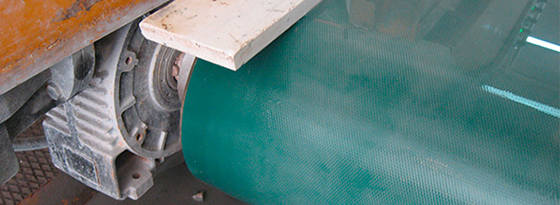

Wood and Raw Materials – we can develop and supply belts to suit the handling of wood, leather and ceramics, glass and marble. Speak to anyone of our team to find out which belting material best suits your purposes.

Cutting and Punching – for obvious reasons cutting and punching places a huge stress on belts. Precision is key in this industry. This is why all our belts are put through a rigorous quality checking procedure. This means that the belts are exactly what the clients requires, not a mm more or less.

If you are unsure of which belt or resistant material best suits your needs, simply give us a call. Our team know the technical aspects of each belt, and our team of sales engineers have worked in the belting industry for a number of years, and are perfectly placed to advise you. Just call us on 01977 691 880.