The Revolutionary HP Compact Drive

Chiorino have always been at the forefront of belting and resistant materials. However, one new development has got everyone at Chiorino a little more excited than usual. The new HP Belt is set to make huge changes to the food industry.

We were asked by a few clients to see how we could help them improve processes in their food plants. So, we took things right back to the drawing board and developed a belt which specifically tackled the most prevalent problems in the food production industry.

What we came up with was the HP belt. One of the most common issues food production facilities have is their belts cracking and splitting. Due to the regular, deep cleans that must be performed to make sure that the facility adheres to hygiene standards, the belts that are currently used start to degrade. When they degrade they split and crack. These smalls splits are the perfect place to for bacteria to accumulate and breed.

This means that most belts have a shelf life which is nowhere near as long as it should be. The HP material was developed to tackle this exact issue. It is extremely resistant to frequent cleaning, making it virtually crack resistant. This means it has a far longer operational life than most belts.

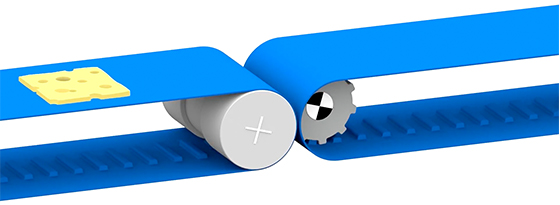

To further improve its functionality we have developed a compact drive version. Most belts are guided by pulleys, at the junction where these pulleys meet a valley forms. The larger the pulley, the deeper the valley. The deeper the valley the more chance the food will move from its set position, and create issues further down the line.

The HP belt is compatible with micro drive pulleys which are much smaller than standard pulleys, which creates a much shallower valley. This small gap makes for a much smoother transition between belts, which improves optimisation.

To find out more about the astounding HP Compact drive, and it’s uses, just give us a call on 01977 691 880.